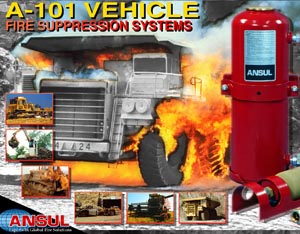

Ansul Vehicle Fire Suppression Systems

Ansul A-101 Off Road Fire Suppression Systems

Features

- FM Approved

- Manual and/or Automatic Detection and Actuation

- Extreme Temperature Option

- Low Profile Tank Option

- Rugged Construction

- Approved For Use in Under Ground Mines For Either Manual or Automatic Agent Release (Automatic Detection System Incorporating MSHAApproved ANSUL® CHECKFIRE® MP-N Detection System)

- CE Marked

Application

The ANSUL A-101 Fire Suppression System is an automatic or manual fire suppression system using FORAY® (monoammonium phosphate base) dry chemical agent for Class A, B, and C fires. The fire suppression system is designed for use on large, off-road type construction and mining equipment (such as large excavators/shovels, draglines, haul trucks, wheeled loaders), underground mining equipment, and specialty vehicles (such as slag, pot and/or slab carriers, tunnel boring machines, solid waste handling equipment, and forestry vehicles). These types of equipment have large volumes of oils and hydraulic fluids under pressure.

The fire system described is a suppression system only and is not designed or intended to extinguish all fires. It is extremely important that alternative firefighting equipment be available in case the system does not totally extinguish a fire.

If an automatic fire detection and actuation system has not been supplied or has been disconnected, system actuation and discharge will not occur unless the fire suppression system is manually actuated.

Description

The ANSUL A-101 Fire Suppression System is a pre-engineered, cartridge-operated dry chemical system with a fixed nozzle distribution network. It is approved by Factory Mutual (FM).

The system is capable of automatic detection and actuation and/or remote manual actuation. When a fire is detected, the A-101 system is actuated either manually or automatically, operating the pneumatic actuator. The pneumatic actuator ruptures a seal disc in the expellant gas cartridge. This, in turn, pressurizes and fluidizes the dry chemical extinguishing agent in the tank, ruptures the burst disc when the required pressure is reached, and propels the dry chemical through the network of distribution hose. The dry chemical is discharged through fixed nozzles and into the protected areas, suppressing the fire.

The automatic detection portion of the fire suppression system incorporates electric detection, either linear detection wire or spot detection.

In addition, Triple IR flame detectors added to the linear or thermal detection circuit can be utilized for quick fire detection response.

The fire suppression system is capable of providing local application hazard protection for mobile equipment and industrial hazards. In certain industrial hazards, total flooding can be used.

The basic system consists of: Dry Chemical Agent Storage Tank(s), Expellant Gas Cartridge, Distribution Hose and Nozzles, Manual/Automatic Actuator, Automatic Detection System, and Accessories.

Agent Storage Tank – The agent storage tank(s) consists of a welded steel tank, gas tube, brass or aluminum fill cap, agent outlet sealed bursting disc assembly, and instruction nameplate. Tanks for temperature ranges of +32 °F to +120 °F (0 °C to +49 °C) and the LT-A-101-10, have a cartridge receiver and an expellant gas cartridge located on the side of the tank. Low profile and extreme temperature model tanks, (–65 °F to +210 °F (–54 °C to +99 °C)), have a separate cartridge/ pneumatic actuator assembly which is connected to the tank by a high pressure 1/4 in. hose. The tank is painted with a red enamel paint. Agent storage tanks are available in six sizes (10 lb., 20 lb., 30 lb., 50 lb., 125 lb. and 250 lb.).

Mounting Bracket (10, 20, 30, 50) – Tank mounting bracket consists of a rugged, welded steel back plate and clamp arm assembly. The bracket is designed to retain and protect the agent storage tank in the normal hostile environment that these systems are installed in. The bracket is painted red enamel and can be mounted by bolting or welding.

Mounting Ring (125, 250) – The mounting ring for the 125, 250 tanks is fabricated of 1/2 in. steel. The ring conforms to the outline of the tank assembly bottom. The ring can be welded to the mounting surface and the tank can then be bolted to the ring, using the pre-threaded holes in

the ring.

Expellant Gas Cartridge – The expellant gas cartridge is a spun high pressure cartridge containing either carbon dioxide for temperature ranges of +32 °F to +120 °F (0 °C to +49 °C), or nitrogen for extreme temperature ranges of –65 °F to +210 °F (–54 °C to +99 °C).

Distribution Hose and Nozzles – The distribution piping (hose) network is designed to properly distribute the dry chemical to the nozzles. To survive the vibration found on mobile equipment, hose is used to distribute the dry chemical. In the A-101 pre-engineered system; hose sizes, maximum and minimum hose lengths, and number of nozzles are predetermined. There are three types of nozzles available for the A-101 system. Each type of nozzle has been designed and tested for various applications and area of coverage. Nozzle blow-off caps are available to keep the nozzles free of dirt and grease.

Manual/Automatic Actuator(s) – The manual actuator consists of an actuator body, a nitrogen cartridge, and a mounting bracket. Two types of manual actuators are available: Remote type and Dashboard type. The Remote type uses either the “S” style bracket or the cartridge guard style enclosure. The Dashboard type uses the “L” or “S” style mounting bracket. When the manual actuator is operated by hand, gas supplied from the nitrogen cartridge is released into 1/4 in. actuation hose. This nitrogen pressure then operates the pneumatic actuator that punctures a larger expellant gas cartridge (either carbon dioxide or nitrogen) and this fluidizes and propels the dry chemical from the agent storage tank. Automatic actuators (a component of the automatic detection system) operate the same way, except they can be operated automatically by the detection system.

Automatic Detection System – Three automatic detection systems are available for use with the ANSUL A-101 fire suppression systems: CHECKFIRE Series I, CHECKFIRE SC-N, or the CHECKFIRE MP-N. Mounting location temperatures for the control modules for the detection

systems are as follows:

CHECKFIRE Series I : –40 °F to +140 °F (–40 °C to +60 °C)

CHECKFIRE SC-N : –40 °F to +140 °F (–40 °C to +60 °C)

CHECKFIRE MP-N : +32 °F to +120 °F (0 °C to +49 °C)